Demag Cranes & Components GmbH in Wetter relies on powder and wet paints from Brillux Industrial Coatings Perfect color matching: powder and wet coatings

Demag Cranes & Components GmbH in Wetter is a leading global supplier of industrial cranes, crane components and comprehensive services. In 2018, Demag switched the powder and wet painting of its KBK modular light crane system to the Universal Polyester Powder 5940 and the 2K-PUR High-Solid Paint 5731. Brillux Industrial Coatings and Demag worked together to tailor the various paint systems’ gloss levels and color shades to meet Demag’s strict quality standards.

Modular and flexible – the Demag KBK light crane system

Single and double-girder suspension cranes, jib and extending cranes, pillar and wall-mounted slewing jib cranes, stacking and gantry cranes: cranes guarantee speed, safety and exact positioning even for heavy loads and wide spans since they transfer goods of all types over large distances without touching the ground. Demag is the market leader for light crane systems worldwide thanks to the KBK system.

The cranes can be individually set up for loads up to 3.2 t thanks to the modular design, enabling precise implementation of customer-specific needs. Due to the highly modular system adaptability, KBK installations can be quickly transformed and expanded in addition to being seamlessly integrated into any production infrastructure. To ensure a consistent appearance of the crane installations, the components must match each other perfectly in terms of color.

Important: uniform appearance

All steel sections are powder-coated as standard, depending on their size. Complicated pieces are given a manual wet paint finish. The main colors used are RAL 2002 vermilion and RAL 1007 daffodil yellow. The uniform appearance of the Demag cranes is dependent on the wet and powder coatings being uniform – even under the most diverse lighting circumstances. This is where Brillux Industrial Coatings came into play. “As a system provider, we can precisely match the coating materials, so that the color shades in wet and powder coatings match perfectly,” Jan Werges, sales consultant at Brillux Industrial Coatings, explains. “We had advantages in the acquisition because of our production and research and development for wet and powder coatings. Since we have both wet and powder coatings production and R&D under one roof in Unna and the customer has a fixed contact person for each, interest was aroused at Demag.” The initial interest evolved into a solid partnership-based collaboration. All steel sections are coated with industrial paints from Brillux after iron phosphating. Demag operates a continuous production and logistics line for the KBK light crane system, which enables all products to be built in one building and to be shipped directly from there. Powder-coating is available in six different profile sizes with lengths of up to eight meters and seven meters for slewing jib cranes.

“Because industrial coatings are significantly intertwined in company-specific production processes, you don’t just make this change as a side project. The ongoing processes must be validated completely with the new products. This requires trust on both sides,” Jan Werges explains. ”At Demag, color matching is very important because the modularity of the crane construction kit is really put to use here. It is not uncommon for existing crane installations to be removed and reassembled with new or different components. The color tone must match exactly in this circumstance – and in a wide range of lighting settings.”

With Universal Polyester Powder 5940, coating thicknesses are more consistent

Demag relies on long-standing customer and supplier relationships. At the heart of the brand image are innovation, dependability, functionality, safety and dependable service, all of which describe the high quality of Demag industrial cranes and hoists. These high quality requirements were fulfilled by the Universal Polyester Powder 5940. It has great weathering resistance, very high gloss and color stability, good corrosion protection qualities, high surface hardness and excellent abrasion resistance.

“We also tested other powder and wet coatings, but they did not meet Demag”s quality requirements,” says Frank Herstell, Demag’s Head of KBK. “Safety is our top priority,” added Daniel Krupka, Head of Production at Demag. “In our test field, the profiles coated with the Universal Polyester Powder 5940 were put through their paces according to our factory standard.”

Brillux created new standards and measured values in collaboration with Demag’s materials testing department to ensure the desired accuracy. Demag specified a master sample first, while Brillux defined the color corridor within which quality and finish were to be maintained. After achieving the necessary color match, the steel profiles were thoroughly examined at Brillux Industrial Coatings and Demag and had to match. “The tests that we performed during the matching and alignment were included in our laboratory tests,” Daniel Krupka explains. Demag’s powder coating switch has paid off: "With Universal Polyester Powder 5940, we achieve more consistent coating thicknesses in the automated process,” Frank Herstell reports.

Safety is our top priority. In our test field, the profiles coated with the Universal Polyester Powder 5940 were put through their paces according to our factory standard.

Daniel Krupka, Head of Production at Demag

Switch to Brillux 2K-PUR High Solid Paint 5731

The standard and special powders were converted in close collaboration for automated powder coating in two powder booths with 17x GEMA Corona E static guns in the first step. In the meantime, the standard wet coatings used by Demag for larger KBK components have also been changed over. 2K-PUR High Solid Paint 5731 is now used. Like the powder coating, the gloss level and color shade of the smooth, two-component high-solid polyurethane coating have also been adapted. 2K-PUR High Solid Paint 5731 is characterized by fast drying, high coverage, high stability and high mechanical resistance. The main colors here are also RAL 2002 vermilion and RAL 1007 daffodil yellow. Wet painting is a manual process at Demag and is carried out using a two-component mixing system in the Airmix process and by cup gun for small batches. Due to the good matching and alignment of the color shades of both the powder and wet paint, touch-ups are unproblematic.

“We found it very helpful that our wet painters and powder coating plant operators received training at Brillux Industrial Coatings in Unna during the transition. Through the identification of possible errors, our personnel were taught how to anticipate potential causes of error in the coating process early on. This was received very well. We see another plus point in the immediate proximity between Unna and Wetter. This assures that, in the event of a problem, our contact person is immediately available in person,” concludes Daniel Krupka. Following the conversion of standard powder and special powder, as well as standard wet coatings, to Brillux Industrial Coatings, the next step will be the conversion of special wet coatings.

Uncoated/coated

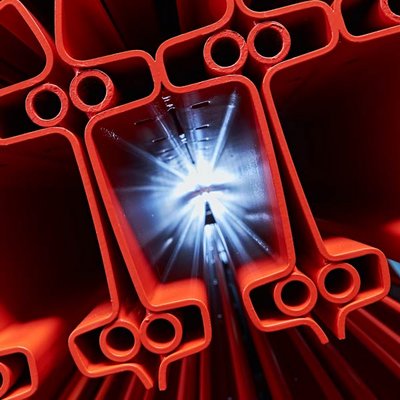

The main colors used are RAL 2002 vermilion (as shown here) and RAL 1007 daffodil yellow). The Demag cranes should have a uniform appearance – regardless of the type of coating.

Demag

The Demag product portfolio includes individual industry solutions for travel tasks, load handling at the workplace and material flow in production and warehouses.

Founded in 1819 as Mechanische Werkstätten Harkort & Co., the company has concentrated on the manufacture of cranes and crane components, including hoists with electric drives, since 1840. Since 2017, Demag has been part of Kronecranes, an international group based in Finland. Time and again, Demag has played a decisive role in shaping the market and has carried out innovative pioneering work. The best example of this is the modular Demag KBK light crane system, which has been built at the Wetter site for more than 50 years and is constantly being developed further.